Description

True Manufacturing’s story began in 1945 when Robert (Bob) J. Trulaske returned from WW II. One night while out at a bar, Bob had the idea of using electric-powered refrigeration for commercial use. With the help of some family members, the first ever commercial refrigeration units were born. Today, that same innovation and passion is carried out by Bob’s son, Steve Trulaske, the current CEO of True Manufacturing. True uses quality components to ensure a long life of refrigeration with minimal energy consumption. State of the art components such as energy efficient compressors and electrically commutated motors are used to exceed energy standards. True continues its commitment to sustainability with the use of foamed in place, CFC free, polyurethane, high-density insulation that provides unparalleled strength, rigidity, and increase to an already industry-exceeding insulation factor. By matching and balancing hydrocarbon refrigeration with the latest refrigeration components.

At True, they are not only interested in a leadership role in the commercial refrigeration industry, but also as a leader and model in efficient, responsible manufacturing worldwide. This includes reducing our carbon footprint and being committed to responsible and sustainable manufacturing. True is proud to have pioneered R290 hydrocarbon refrigerant. Hydrocarbons have no ozone depleting properties and are over 1300 times better for the environment than HFC refrigerants. True is committed to our green promise as well as continuing to make your world cooler

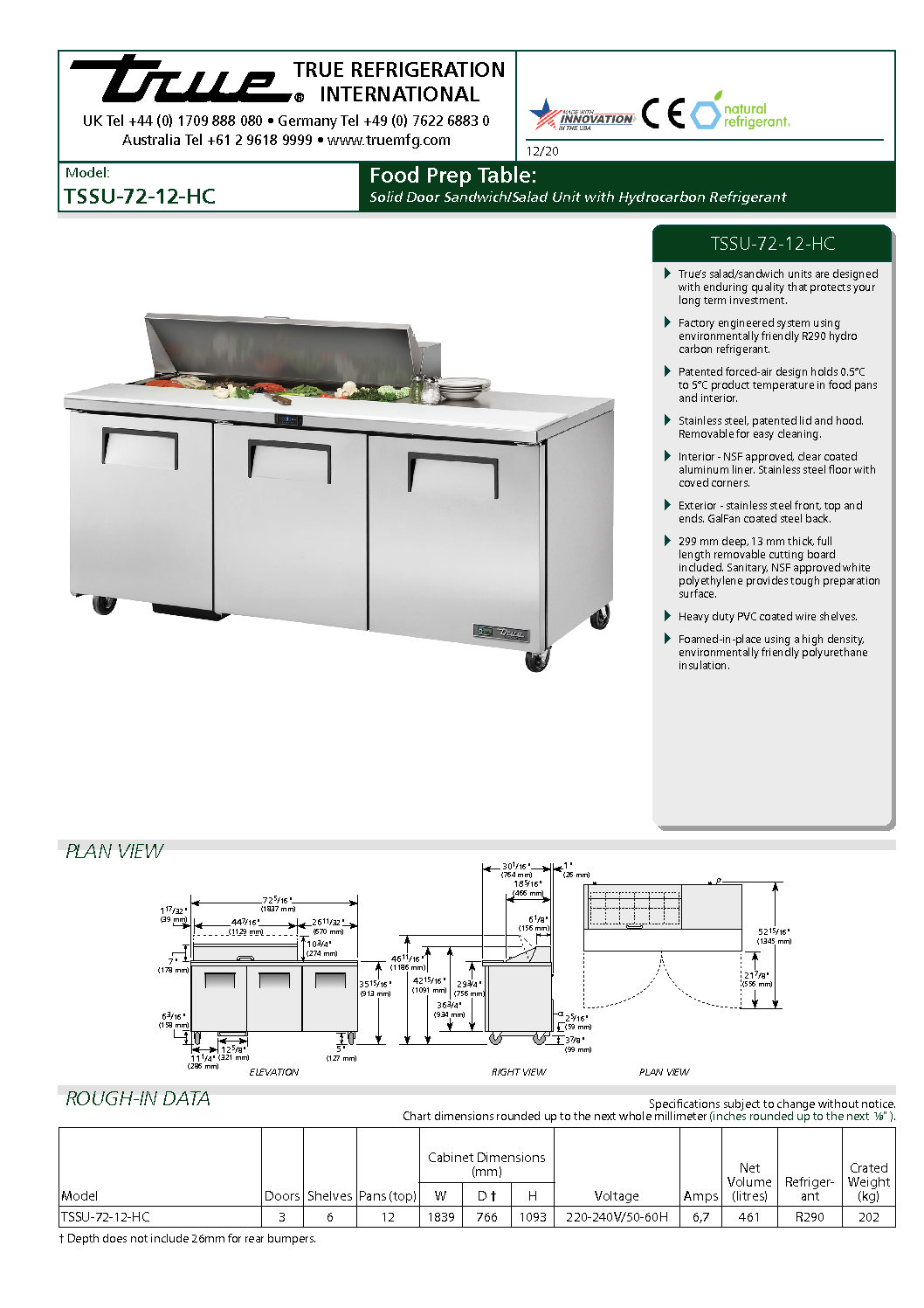

TSSU Prep Counters are ideal for sandwich preparation, featuring configurable Gastronorm pan space, able to accommodate a combination of pan sizes tailored to your operation, with large capacity refrigerated storage for easy replenishment. TSSU prep tables offer the widest range of model sizes and build options, including door/drawer, lid and pan number options.

For help choosing the correct TSSU series cabinet follow the link to view the full range – True TSSU Series Cabinets & to view Trues entire prep table range

The Best Pan Temperatures

TSSU products feature our most advanced prep table refrigeration system, with a unique airflow system which more accurately maintains a consistent 0.5°C to 5°C temperature range, ensuring the very best in ingredient preservation.

Using Hydrocarbon refrigeration systems, the latest in energy efficient components and our own patented technologies, our commercial refrigeration equipment is highly efficient, environmentally friendly and doesn’t sacrifice on performance.

Tailor your Gastronorm pans to your menu, with flexible space for your choice of pan sizes and combinations. Mix door and GN pan drawer options allow you to configure your prep station to your operation.

For customer-facing operators which want to put freshness on display, our hydraulic glass lid TSSU variations provide maximum product visibility while ensuring food-safe pan temperatures.

Our patented reversing condenser fan motor reverses during defrost off cycles to help keep condenser coil free from dirt, dust and debris. This optimises the unit’s performance, increases energy efficiency and reduces system failure.

SPEC Upgrade

True’s ‘Spec’ option offers an upgrade to product aesthetics and durability, with all stainless-steel construction in and out, heavy duty 16-gauge top and 20-gauge doors and a lifetime-guaranteed all-metal working door handle.

Our patented RCU motor periodically reverses the rotation direction of the condensing fan, helping to remove excess debris from the interior and surface of the condensing coil. This optimises the unit’s performance and increases energy efficiency.

TSSU products are 100% front-breathing, with zero operating clearance to the unit sides and back required, allowing for built-in installation. It can be specified with a ‘biscuit top’ for installation under a fabricated counter (cabinet height = 840mm).

All True products are foamed in-place, using a high-density polyurethane insulation that has zero ozone depletion potential and zero global warming potential.

Through extensive development and testing, our products maintain consistent, accurate and safe storage temperatures, even in the most demanding foodservice environments.

True’s Hydrocarbon products harness the power of R290, to produce highly energy efficient and environmentally friendly commercial refrigeration equipment which doesn’t sacrifice on performance.

All True products are supplied with a five-year parts and labour warranty as standard. Our Australia-based customer and technical support teams are waiting to take your call.

We ensure quality by having complete control of our full manufacturing process. Every True product produced is the result of over 75 years of experience. Quality is assured.

Our complete refrigeration equipment range includes over 300 industry-leading products, with sizes, options and accessories to fit any application. All covered by 5 Years warranty as standard.

Specification:

- Capacity: 538 Litres

- Dimensions external: 1093(H) x 1839(W) x 766(D)mm

- Number of shelves included: 6

- Temperature range: 1°C to 3°C

- Max operating temperature: 40°C

- Power type: 230V/50Hz/1Ph – 13Amp

- Refrigerant: R290

- Crated Weight: 202kg

- Colour: Stainless steel

- Warranty: 5 Years parts & warranty

Product Features

- True’s salad/sandwich units are designed with enduring quality that protects your long term investment.

- Factory engineered, self-contained, capillary tube system using environmentally friendly R290 hydro carbon refrigerant that has zero (0) ozone depletion potential (ODP), & three (3) global warming potential (GWP).

- Patented forced-air design holds 0.5°C to 5°C product temperature in food pans and cabinet interior.

- Complies with and listed under ANSI/NSF-7.

- Exterior – stainless steel front, top and ends. Corrosion resistant GalFan coated steel back.

- Stainless steel, patented, foam insulated lid and hood keep pan temperatures colder, lock in freshness and minimize condensation. Removable for easy cleaning.

- Interior – attractive, NSF approved, clear coated aluminium liner. Stainless steel floor with coved corners.

- 11 3/4 ” (299 mm) deep, 1/2 ” (13 mm) thick, full length removable cutting board included. Sanitary, high density, NSF approved white polyethylene provides tough preparation surface.

- Heavy duty PVC coated wire shelves.

- Foamed-in-place using a high density, polyurethane insulation that has zero ozone depletion potential (ODP) and zero global warming potential (GWP).

NOTE – American import for UK may take longer than delivery times stated. For live update please contact us.

Reviews

There are no reviews yet.